EPS is abbreviated from Expanded Polystyrene or styrofoam, and EPS machine refers to polystyrene foam manufacturing.

The EPS machine has a set of different equipments, including EPS pre-expander, EPS block moulding machine, EPS cutting machine, EPS recycling machine, EPS sandwich panel machine, auxiliary equipment and etc.

The EPS machine can be divided into intermittent and continuous pre-setting types.

The automatic molding machine is widely used in electric foam packaging, fruit and vegetable foam boxes, and various packaging products.

-300x300.webp)

Do you know how styrofoam is formed? And the styrofoam moulding machine can process many kinds of polystyrene materials.

EPS machine is the machine that is used to produce the Expanded (E) Polystyrene (PS) products.

EPS is a lightweight cellular plastic material that is commonly used for packaging, insulation, and construction applications. The EPS machine, also known as an EPS molding machine or EPS processing machine, is designed to shape and mold EPS beads into various forms, such as foam packaging, insulation boards, and other EPS products. These machines typically involve processes like pre-expansion, molding, and cutting to produce the final EPS products according to specific shapes and sizes.

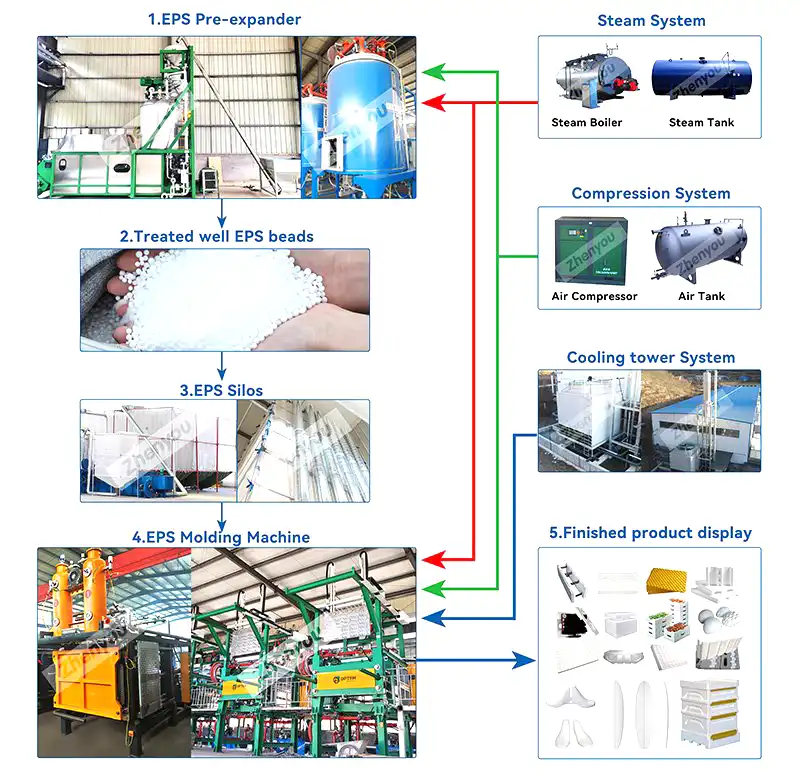

The working theory of an EPS machine involves several key steps in the production of Expanded Polystyrene (EPS) products:

Pre-Expansion: In this initial stage, EPS beads are pre-expanded using steam to achieve the desired density. This process makes the beads more malleable and ready for molding.

Molding: The pre-expanded beads are then transferred to a mold cavity within the EPS machine. Steam is applied again, causing the beads to expand further and fuse together. The mold is typically shaped according to the desired end product.

Cooling: Once the molding process is complete, the formed EPS product undergoes a cooling phase. This ensures that the material solidifies and retains its intended shape.

Cutting: After cooling, the EPS block or product is cut into specific shapes and sizes. This cutting process may be accomplished using hot wires or other cutting mechanisms.

Shaping and Finishing: Some EPS machines may include additional steps for shaping and finishing the products. This could involve further cutting or shaping to meet precise specifications.

Quality Control: Throughout the entire process, quality control measures are implemented to ensure that the produced EPS products meet the required standards in terms of density, shape, and other specifications.

EPS machine can be widely used for various industries, and here are some trending EPS machine applications in the following:

EPS machine can used to produce the packaging for vegetables, fruits, electronics and etc.

EPS moulding machine can process sandwich panel, brick insert, insulated foam and etc for building materials.

EPS machine can work out the decoration materials, such as ceiling, panel, title and etc for decoration.

EPS machine can produce the filter material for the scaled water supply systems.

EPS moulding machine can process sandwich panel, brick insert, insulated foam and etc for building materials.

EPS machine can work out the decoration materials, such as ceiling, panel, title and etc for decoration.

Copyright © 2024 Hangzhou Epsole technologies Co.Ltd.