Importing EPS Moulding Machine for EPS from China

Are you still looking for the qualified EPS moulding machine? Epsole is the leading EPS manufacturer with full capacity to provide high-performance EPS mould machine.

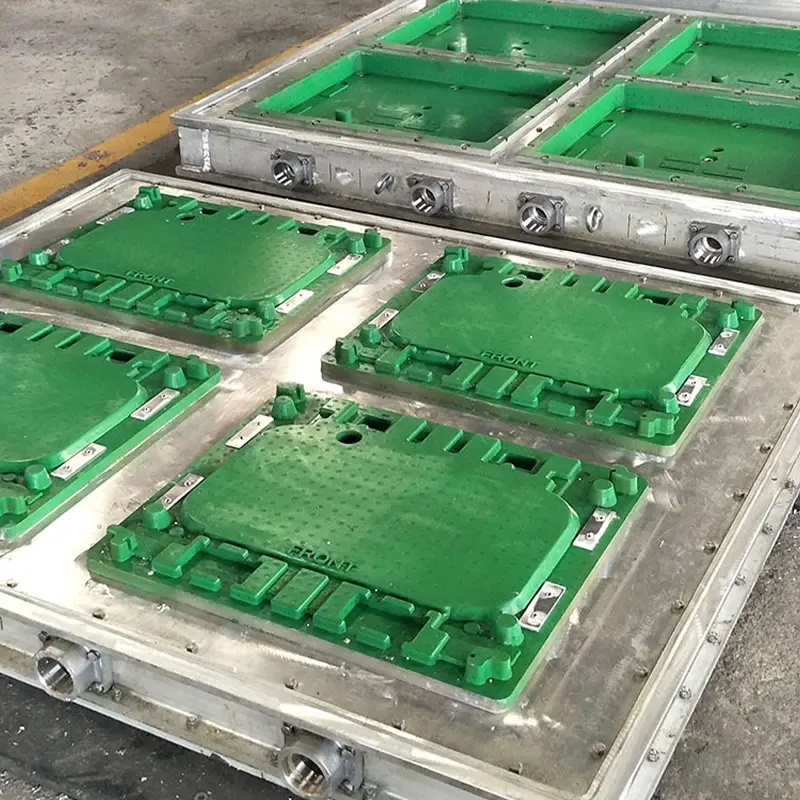

Our EPS Moulding Machine

We are one of the best EPS moulding machine manufacturers to manufacture the high-efficiency EPS moulding machine for the expandable polystyrene production.

Mold Heating System: EPS molding machines are equipped with a mold heating system that ensures the proper temperature for molding EPS beads into desired shapes.

Steam Generation and Distribution: Steam is used to expand EPS beads within the mold cavity. The steam generation systems provide consistent steam supply to the molds with precise control over steam pressure and distribution to ensure quality and uniformity in the molded products.

Material Feeding Mechanism: EPS beads, the raw material for molding, are fed into the machine through a feeding mechanism. This mechanism ensures a continuous and accurate supply of EPS beads to the molding process, optimizing production efficiency.

Pressure Control System: Controlling the pressure during the moulding process is crucial for achieving the desired density and strength in the final EPS products.

Cooling System: After moulding, the EPS products need to be cooled down to solidify their shape. EPS molding machine cooling systems can rapidly cool down the molded products, allowing for quick demolding and minimizing production cycle times.

EPS Moulding Machine Special Features

Automatic Pressure Adjustment

Certain EPS molding machines are equipped with automatic pressure adjustment systems that dynamically regulate the pressure inside the mold cavity during the molding process. This feature optimizes the molding parameters in real-time, resulting in consistent product quality and reduced operator intervention.

Quick Changeover Capability

EPS molding machines with quick changeover capabilities enable rapid switching between different molds or product configurations. This feature is particularly beneficial for manufacturers producing a variety of EPS products, as it reduces downtime and improves overall production efficiency.

Foam Density Control

Advanced EPS molding machines may offer foam density control features, allowing operators to precisely adjust the density of the molded EPS products. This capability is essential for meeting specific performance requirements and ensuring consistent product quality across production batches.

EPS Foam Moulding Machine Applications

Packaging Industry

These machines are used to create protective packaging inserts, cushioning materials, and insulating containers for various products. By molding EPS foam to fit specific shapes and dimensions, these machines ensure secure packaging that protects items during transit, minimizing the risk of damage.

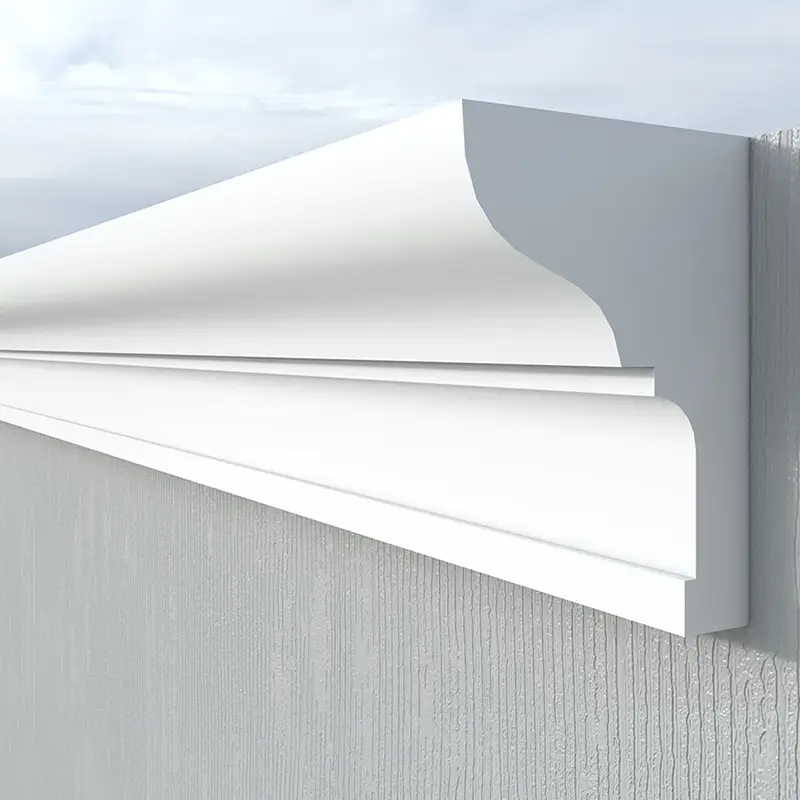

Construction Sector

EPS foam moulding machines are extensively employed in the construction sector for producing architectural and insulation components. These machines are used to manufacture EPS foam blocks, panels, and architectural details such as cornices, columns, and facade elements. The lightweight yet durable nature of EPS foam makes it an ideal material for insulation and construction, providing thermal and sound insulation properties.

Automotive Industry

EPS foam moulding machines are utilized in the automotive sector for manufacturing interior components and protective packaging. These machines shape EPS foam into parts such as headliners, door panels, and seat cushions, providing lightweight and impact-absorbing solutions that enhance passenger comfort and safety.

Why Choose Our EPS Moulding Machine

- Efficiency: Our EPS moulding machine is engineered for optimal efficiency, ensuring rapid processing of expanded polystyrene (EPS) materials into precise and high-quality shapes. Equipped with advanced technology and cutting-edge features, our machine streamlines the moulding process, saving you valuable time and resources.

- Versatility: Our EPS moulding machine is versatile and capable of moulding various shapes and sizes, catering to a wide range of applications. Whether you need to produce packaging inserts, architectural elements, or custom-designed products, our machine delivers consistent and adaptable performance.

- Quality Output: We prioritise the quality of moulded EPS products produced by our machine. With meticulous craftsmanship and top-grade components, we guarantee that the moulded EPS meets industry standards and your specific requirements. You can rely on our machine to create durable and precise shapes for diverse uses.

- Sustainability: Opting for our EPS moulding machine reflects your commitment to sustainability and eco-friendly practices. By using recycled EPS materials and efficient moulding techniques, our machine helps reduce waste, conserve resources, and promote sustainable manufacturing processes.

- Support and Service: When you invest in our EPS moulding machine, you receive comprehensive support and service from our experienced team. From installation and training to ongoing maintenance and technical assistance, we’re dedicated to ensuring the smooth operation and longevity of your moulding equipment.

FAQs

What is an EPS molding machine?

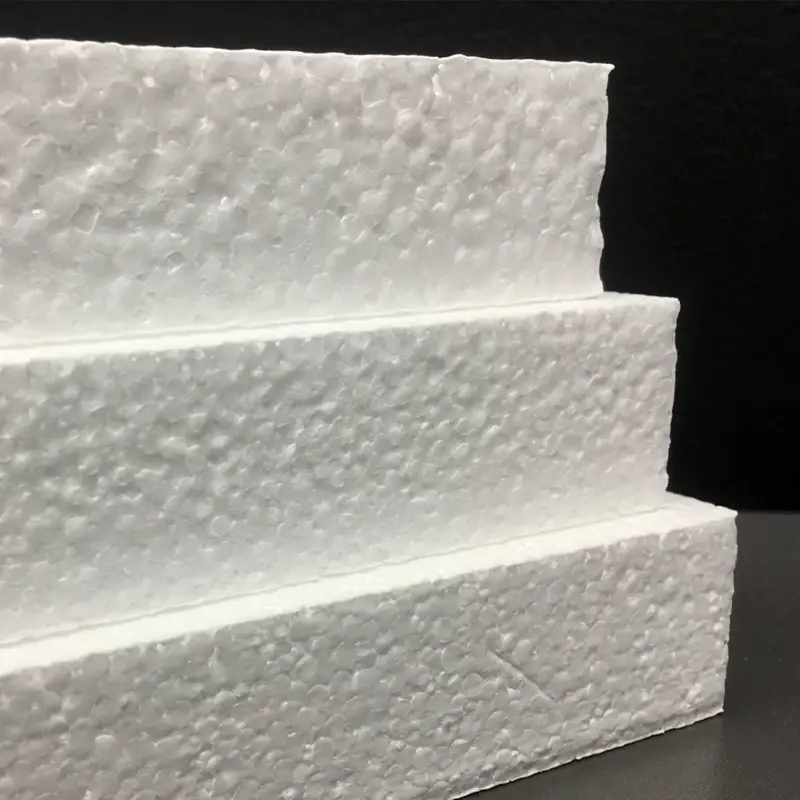

An EPS molding machine is a specialized industrial machine used to manufacture products made from Expanded Polystyrene (EPS), such as packaging materials, insulation panels, and molded shapes. It processes EPS beads by heating them and expanding them into a mold cavity to form the desired shape.

How does an EPS molding machine work?

EPS molding machines work by heating EPS beads to a controlled temperature and then expanding them using steam pressure within a mold cavity. Once expanded, the EPS material solidifies into the shape of the mold, producing the final product.

hat types of products can be made with an EPS molding machine?

EPS molding machines can produce a wide range of products, including packaging materials (e.g., protective packaging, containers), insulation panels (e.g., for construction, refrigeration), molded shapes (e.g., architectural decorations, product components), and even custom designs based on specific requirements.

What are the main components of an EPS molding machine?

The main components of an EPS molding machine typically include a mold heating system, steam generation and distribution system, material feeding mechanism, pressure control system, cooling system, automation and control panel, and safety features such as emergency stop buttons and safety guards.

What are the benefits of using an EPS molding machine?

The benefits of using an EPS molding machine include high production efficiency, versatility in product design, lightweight yet durable products, excellent insulation properties, cost-effectiveness, and the ability to recycle and reuse EPS material, contributing to sustainability efforts.

How do I choose the right EPS molding machine for my production needs?

When choosing an EPS molding machine, factors to consider include production capacity, product specifications (size, shape, density), energy efficiency, automation features, reliability, after-sales support, and budget. It’s essential to evaluate your specific requirements and compare different machine models before making a decision.

What maintenance is required for an EPS molding machine?

Regular maintenance of an EPS molding machine is essential to ensure optimal performance and longevity. This may include cleaning, lubrication, inspection of components, calibration of temperature and pressure settings, and replacement of worn parts as needed. Following the manufacturer’s maintenance guidelines is recommended.

Can an EPS molding machine be upgraded or customized?

Yes, many EPS molding machines offer options for upgrades or customization to meet specific production requirements. These may include adding additional heating zones, integrating automation features, upgrading control systems, or retrofitting with energy-saving technologies. Discussing customization options with the manufacturer or supplier is advisable.

What safety precautions should be followed when operating an EPS molding machine?

Operators should receive proper training on the safe operation of EPS molding machines and adhere to all safety guidelines provided by the manufacturer. This includes wearing appropriate personal protective equipment, avoiding contact with hot surfaces, using caution around moving parts, and following proper shutdown procedures in case of emergencies.

Where can I purchase or learn more about EPS molding machines?

EPS molding machines are available from various manufacturers and suppliers worldwide. You can inquire about purchasing options, request product specifications, or seek technical assistance directly from the manufacturer or through authorized distributors. Additionally, industry trade shows, online marketplaces, and professional associations may provide valuable resources and information about EPS molding technology.